CASE STUDY

APPLICATION & CLOUD SERVICES

ENABLING

DIGITAL SOLUTIONS

INTERNET OF THINGS (IoT)

Increase productivity through processing and analysis of manufacturing data

PROJECT OBJECTIVES

Our client had a vision of data processing platform offered to his customers to analyze inefficient parts of manufacturing process, detect down time and bottlenecks and be alarmed on issues in smart factories in near real-time.

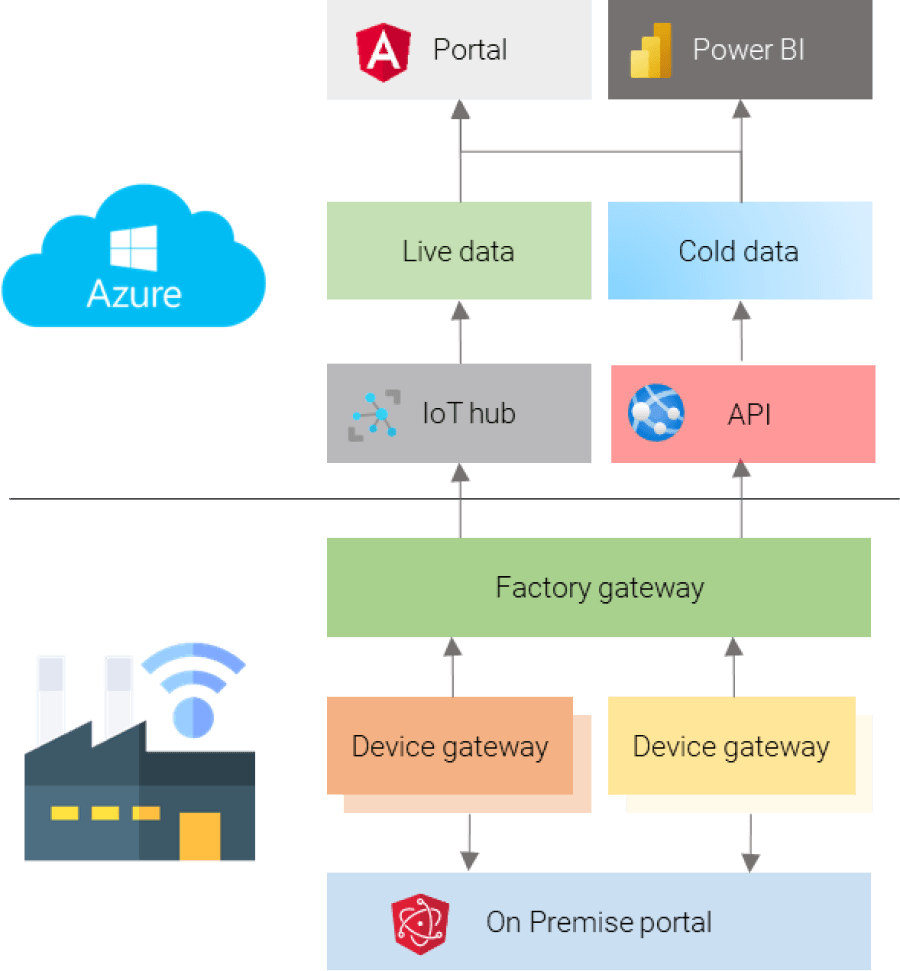

As a part of their digital product initiative, a data processing platform for manufacturing data was architected , which would add extra value to their customers and generate additional revenue streams. End users would gain access to collected live and cold data through custom dashboards and Power BI reports.

- Highly scalable and robust cloud solution on Microsoft Azure

- Modular and easily extensible with loosely coupled technical and business modules

- Hybrid-Cloud compatible

- 3D/Augmented reality visualization in web browser

- Composite user interface that is highly customizable

- Localizable solution – new languages can be added without extra development

CUSTOMER BENEFITS

The platform was central point to connect devices, systems and customer data. The customer was the centric piece of information, defined once and used to reference all other customer related data generated on the platform.

This guaranteed customer data reusability, development cost optimization, and unified end-user experience on existing or new digital projects developed in the organization.

- Live streamed data processing in cloud and on-premises solution with minimal delay and customizable data representation through widget-like system

- Manufacturing data analysis with artificial intelligence used for remaining tool life calculation as well as potential breakage detection.

- Power-BI reports for advanced user experience and interactivity. This presentation brings easily extensible UI with a wide range of inbuilt controls and components.

- Azure Data Lakes for reporting data and Azure Machine Learning for advanced analysis and data prediction with well-defined models.

IPS EXPERTISE

Project was launched with a team of architects from client, partners and IPS as a R&D cooperation. Client was an early adopter into the Azure IoT functionality and had vision to optimize and digitalize manufacturing processes for his customers. IPS technical experts helped build architectural skeleton and provided critical technical advice on supported transition to full-fledged project. R&D mindset applied during entire project.

Thanks to deep understanding of machine specialists and measurements of real-time production process, it was possible to detect correct start/end production cycles with 99% certainty.

TECHNOLOGIES USED

IPS has implemented following technology stack troughout the project on behalf of the customer.

- NET 3.1, ASP.NET Core, C#

- Angular 14 , TypeScript, HTML, CSS, Electron

- Azure IoT Hub, Azure Storage, Azure Event Hub

- Azure Service Fabric

- SOA, Web API, HTTP REST

- SSO, IdentityServer, ADFS, Azure AD B2C

- Visual Studio, Azure DevOps, Git, PowerShell

- Microsoft Azure PaaS and SaaS

Ready to go ahead and start a cooperation?

Contact us directly and receive a non-binding proposal.

Ready to go ahead and start a cooperation?

Contact us directly and receive a non-binding proposal.

Fill in the form and we will contact you asap.

For more specific inquiries please contact our sales team via info@ips-ag.com